Amf Dough Divider/Rounder KX-T User Manual Page 3

- Page / 4

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

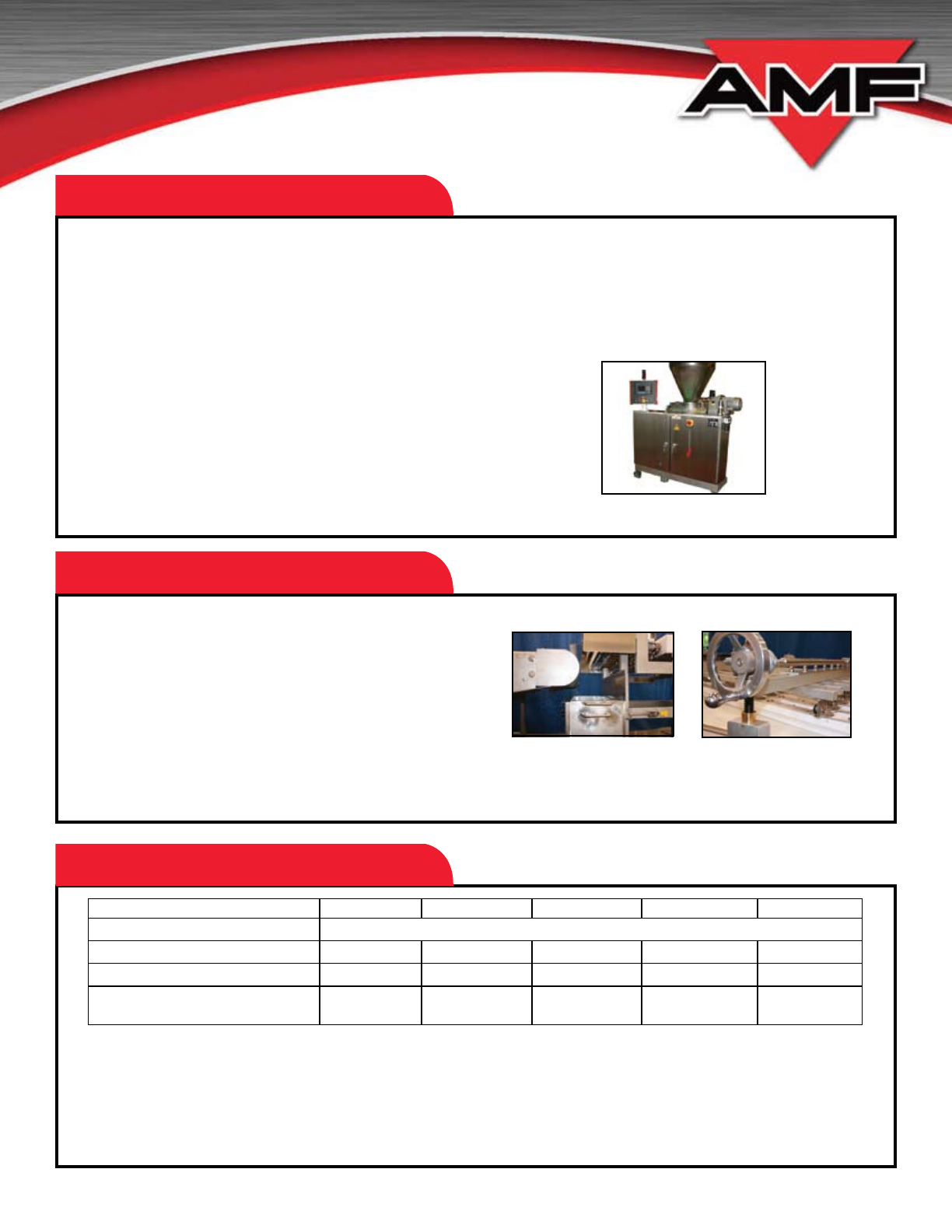

OPTIONS

SPECIFICATIONS

KX-T400 KX-T500 KX-T600 KX-T800 KX-T900

KnifeSpeed 10to135cutsperminute

MaximumPorts 4 5 6 8 9

MaxPiecesperHour 32,400 40,500 48,600 64,800 72,900

TotalThroughputlb./hr.(kg/hr.)

5,000

(2268)

6,000

(2722)

8,000

(3629)

10,000

(4536)

10,000

(4536)

ElectricalRequirements:

ApproximateMainPower:23KVA

ControlPower:24VDC/120VAC

AirRequirements:15SCFM@80PSIG

ApproximateDimensions:

Divider:116”Lx86”Wx82”H(2947mmx2185mmx2083mm)

Rounder:96”Lx84”Wx54”H(2438mmx2134mmx1372mm)

ApproximateShippingWeight:

4,900lb.(2223kg)

ELECTRICAL FEATURES

• NEMA12stainlesssteelcontrolenclosure

-Mountedondividerandpre-wiredforsimpleinstallation

• AllenBradley5/03PLCcontrol

-Synchronizesknifetoprooferspeed

• AllenBradleyvariablespeedACinvertersfor

-Augerdrive

-Meteringpumpdrive

-Rounderbelt

-Kickerroller

• PreciseAllenBradleyservomotordriveforcut-offknife

-Electronicproofersynchkit

• AllenBradleyPanelView600operatorinterfacestation

-Fullrecipemanagementforupto50products

-Simplechangeoverprocedure

-Alarmmessagedisplay

• AllenBradleypushbuttonsfor:

-2buttonstart

-Stopandemergencystop

-Mastercontrolrelay

• Alarmbeacon

• PLCcontrolledCIPsanitationroutine

• Doughpressurecontrolledbytransducerfeedbackloop

Machine Mounted Electrical

Enclosure & Operator Controls

• Optionalchilledrounderbed

• Additionalmachinemanuals

• Pneumaticpushbacksystem

− Allowsdividertodischargeunwanteddoughinto

rollawaystainlesssteelcatchpanwithscreenand

drain

− Dividerwillautomaticallypushbackifscalingunder

weightproductsbasedonpressurefeedback

− Pushbackalsoallowseasyaccessduringsanitation

• Availableadjustableopeningrounderbarsystemfor

preciseroundingcontrolofalldoughpiecesizes

• Reverseaxisrounderbars

• CEelectricals

Pushback with Catch Pan Adjustable Bars

Comments to this Manuals